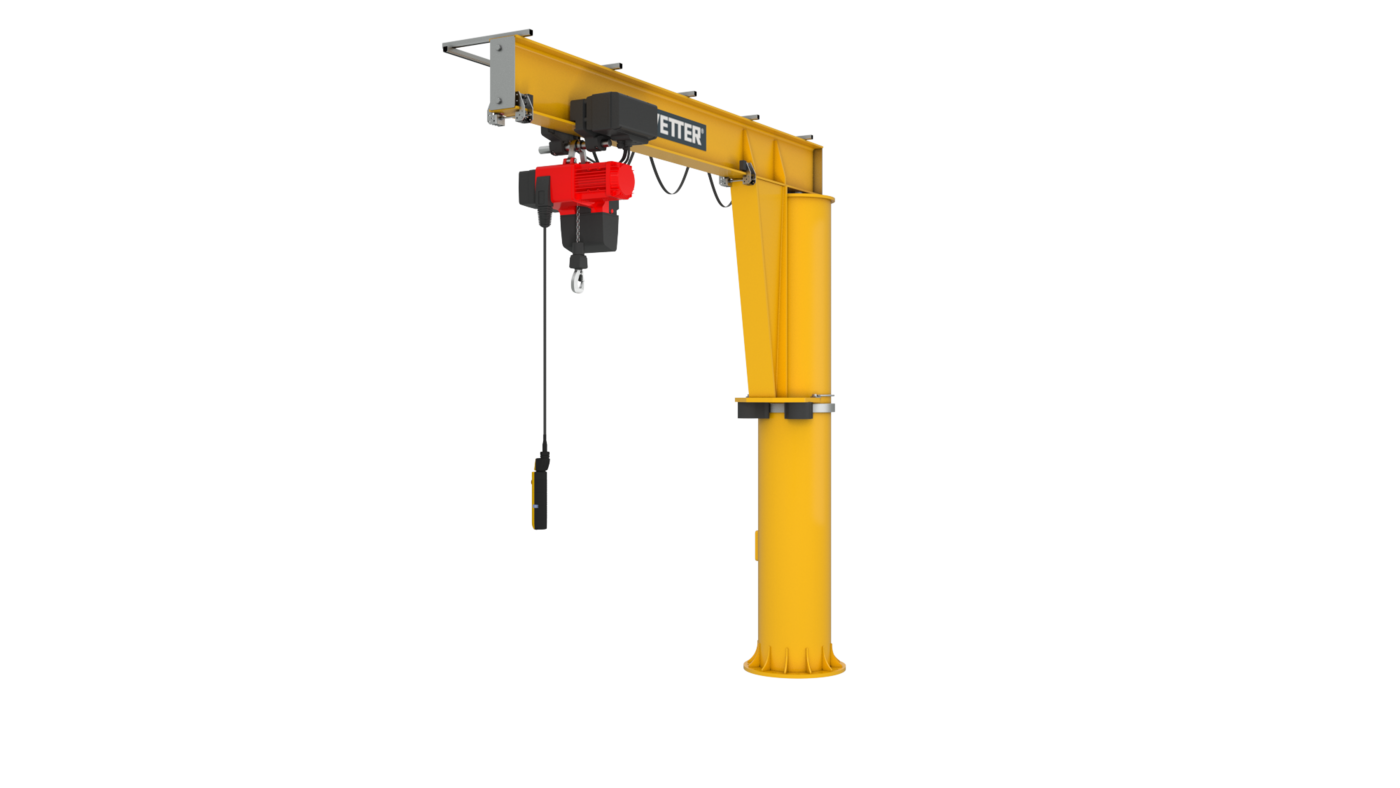

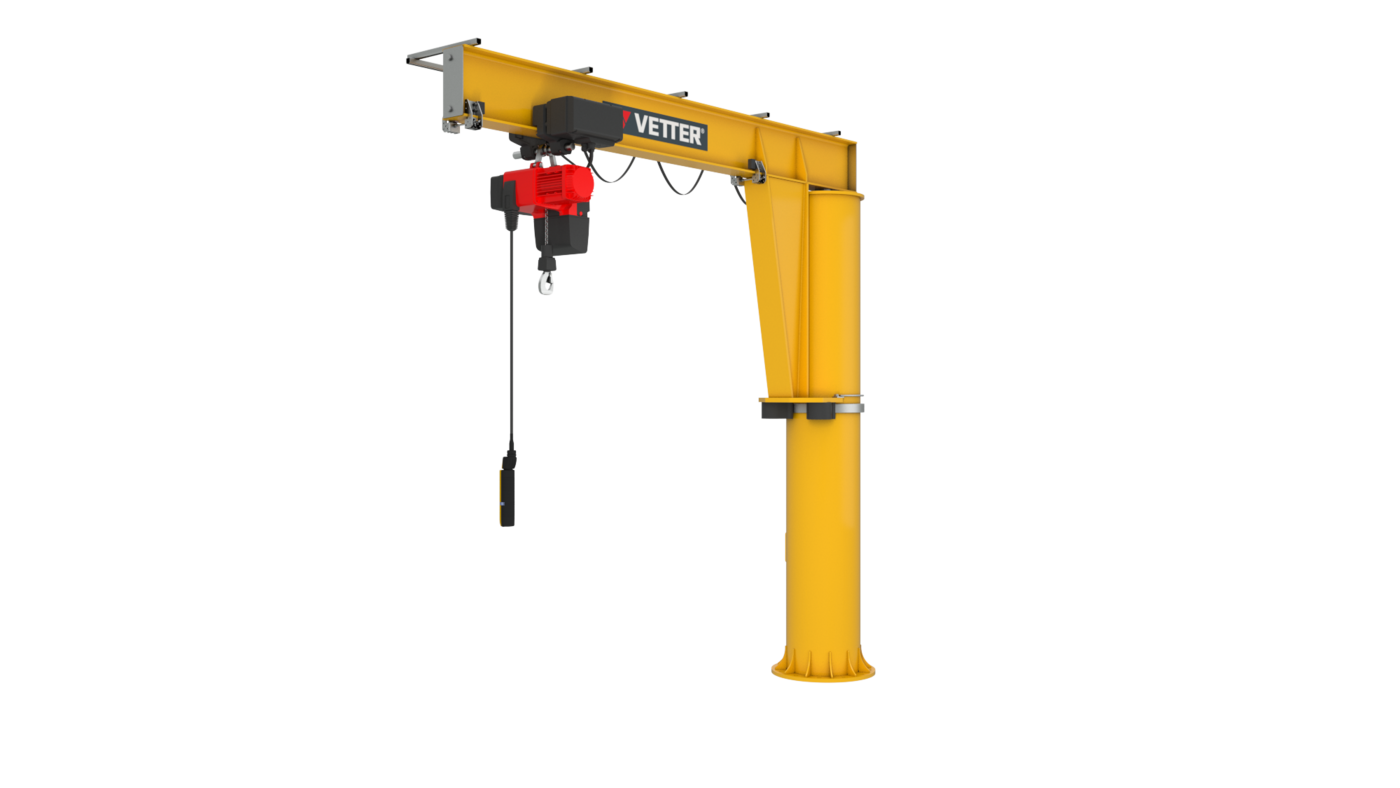

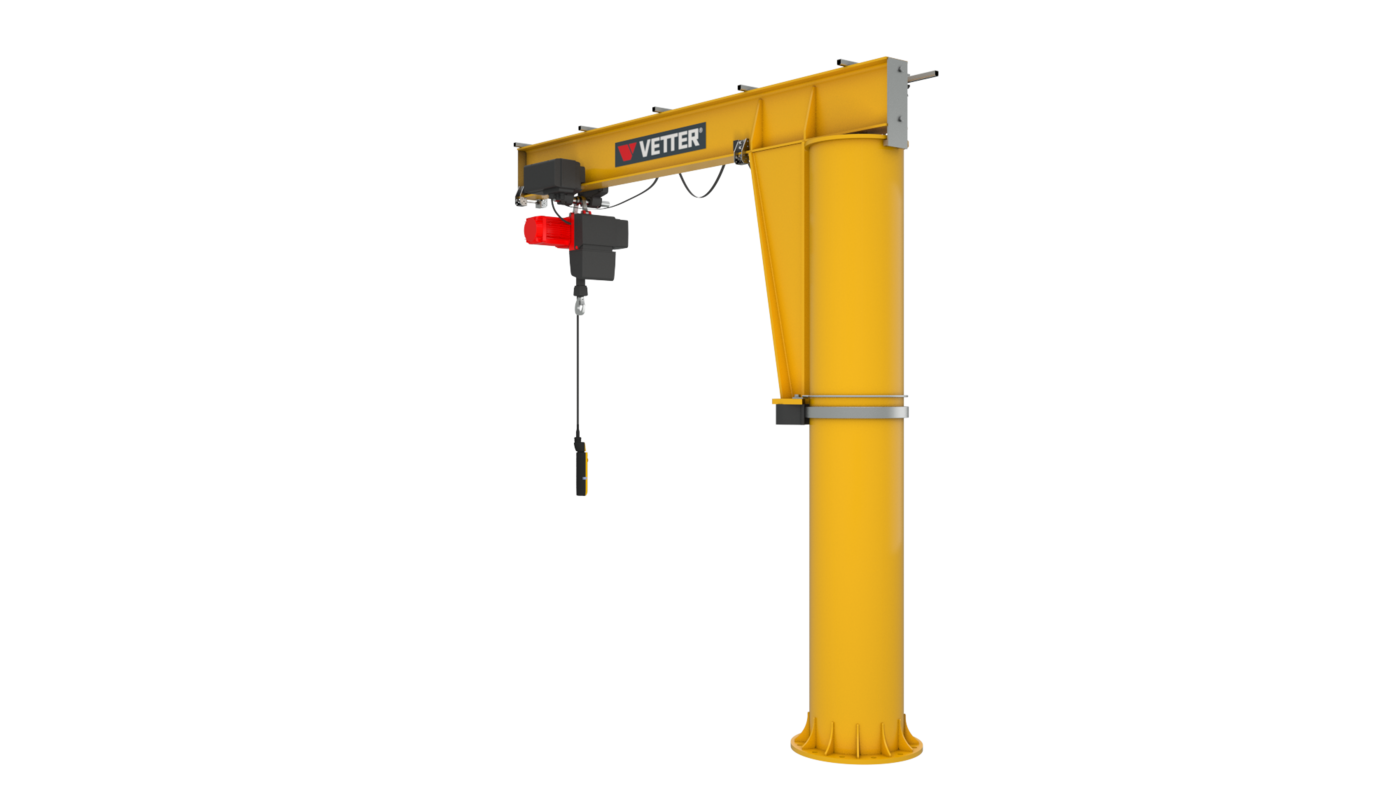

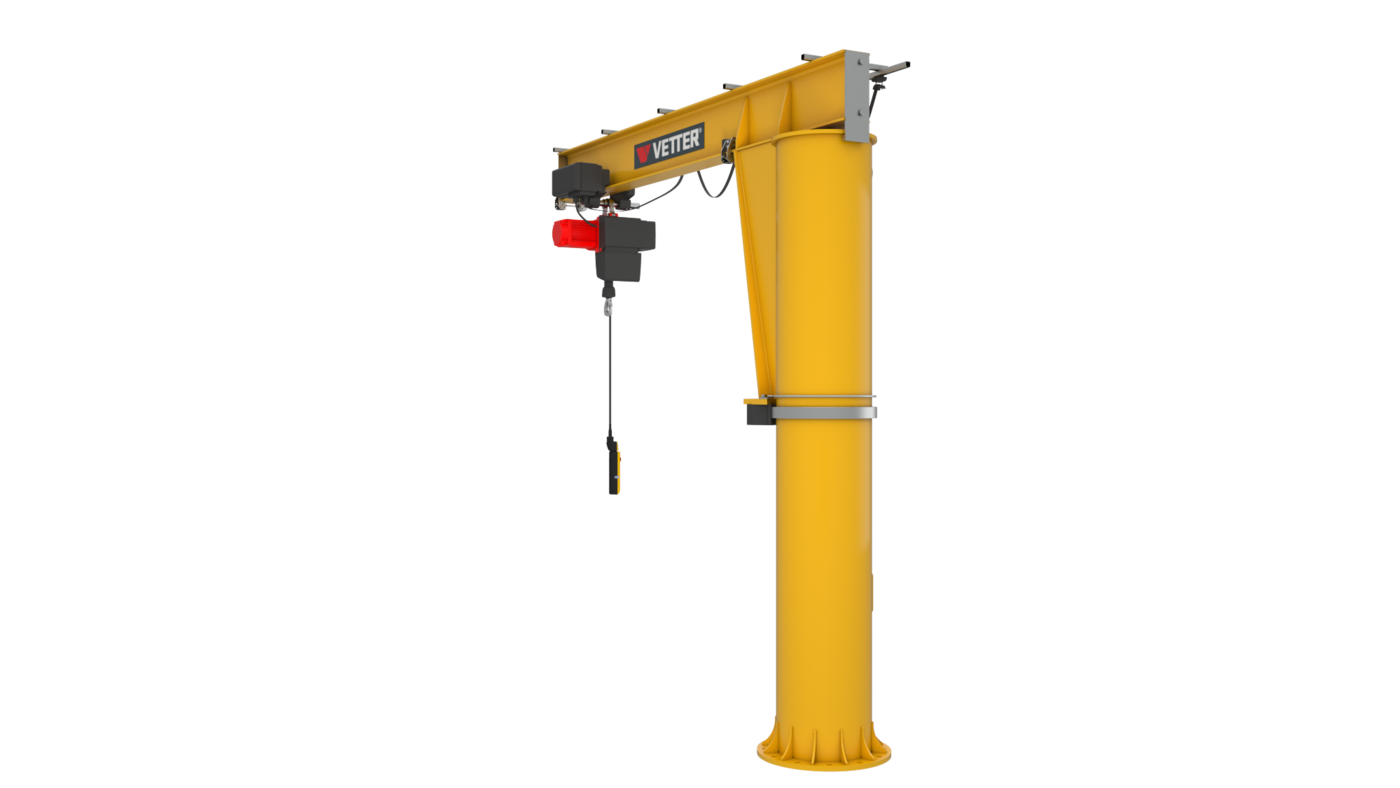

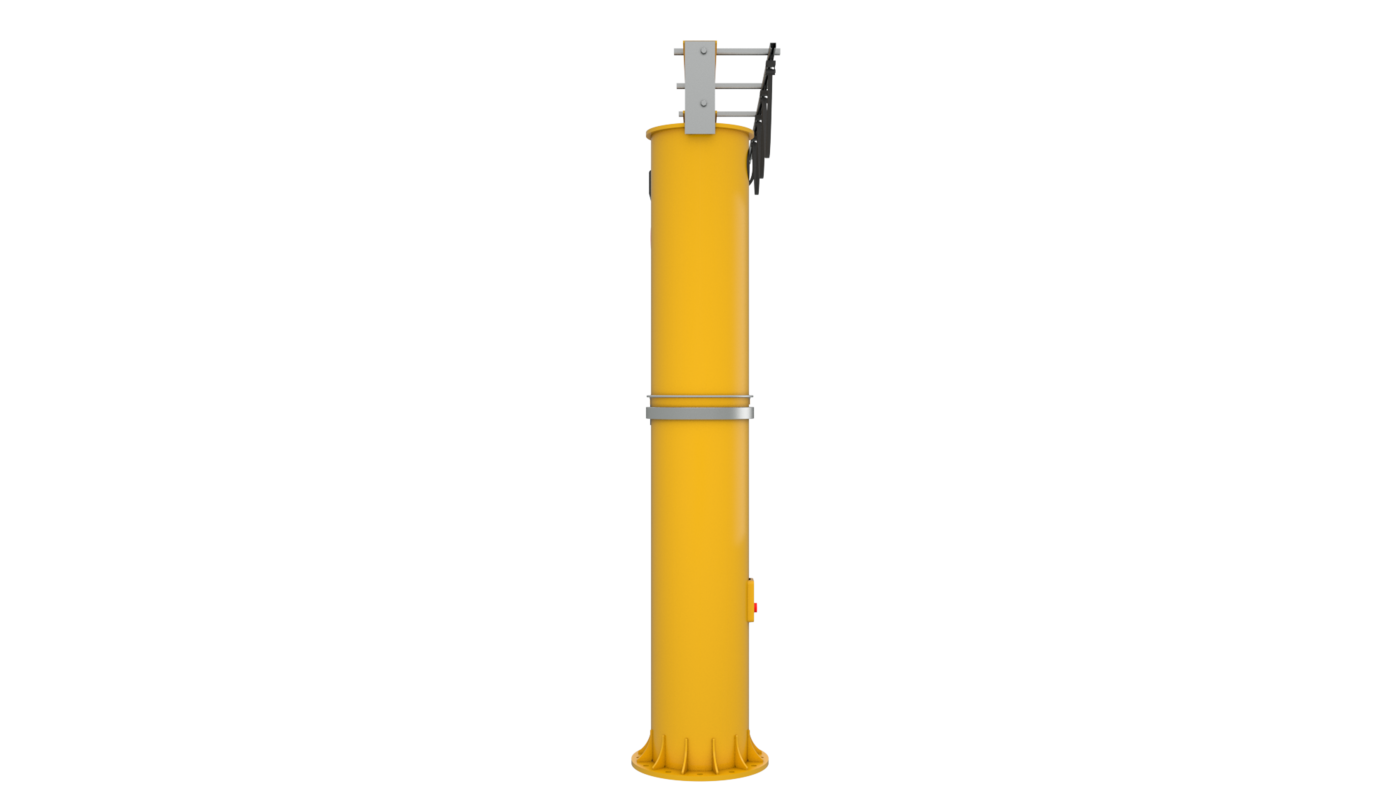

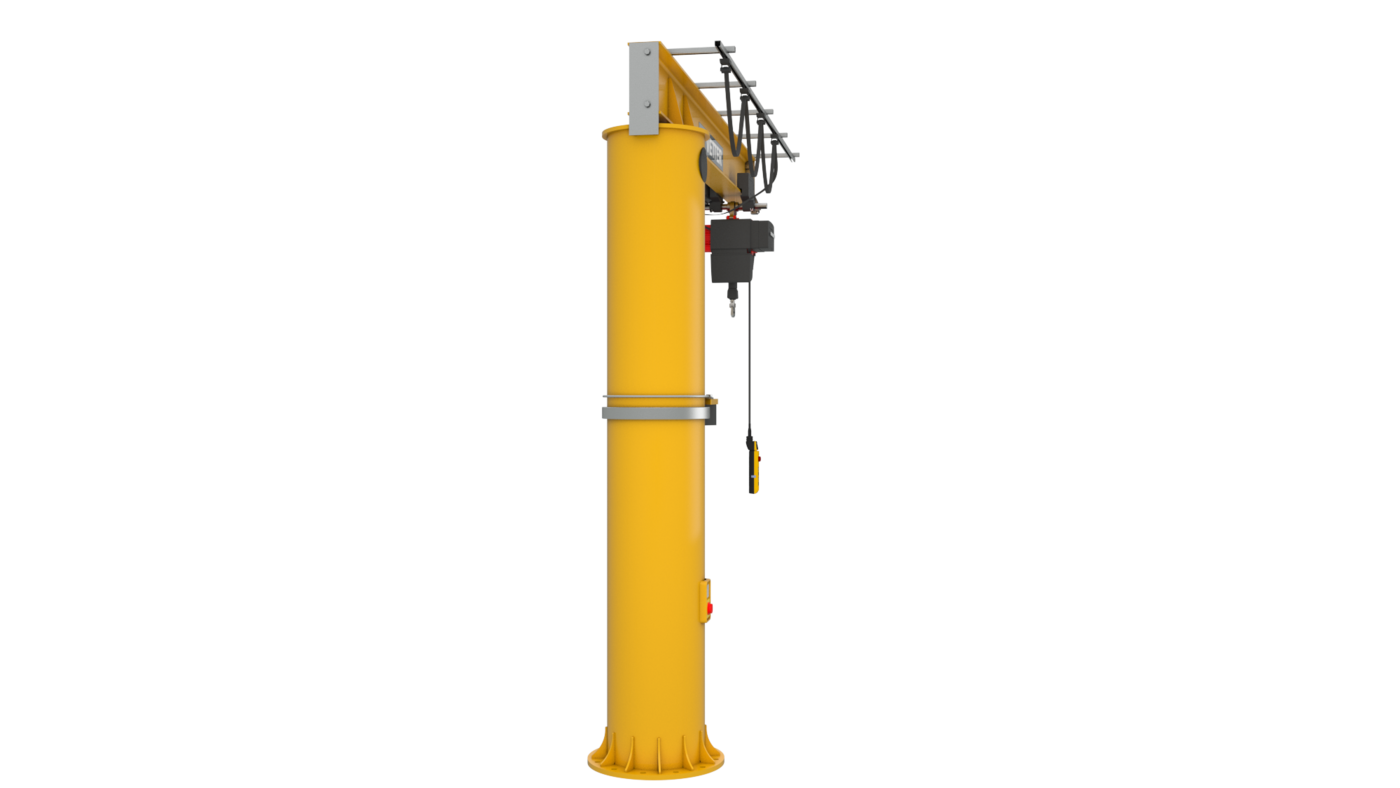

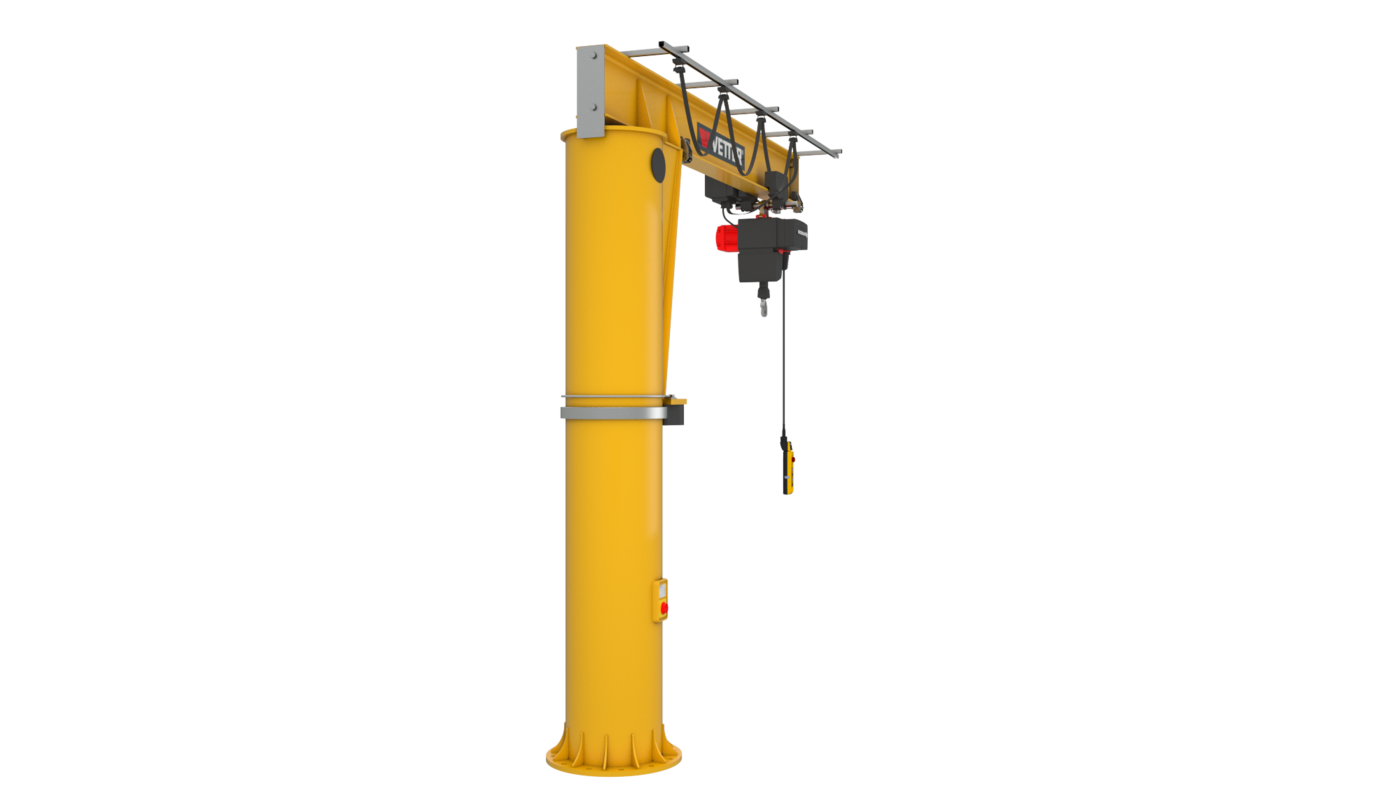

Column-mounted slewing jib crane

Type M

Tip The DowelPlate system VAS2 can be used to fasten the crane.

Product highlights

- Infinite slewing by 360° thanks to power supply by slip-ring assembly

- Comfortable and smooth slewing possible by means of electrical slewing gear (optional)

- Compact design, perfectly suited for small rooms

- Large effective lifting height

- Outdoor use possible

- Suitable for explosion protection according to ATEX (option)

- Column height and jib arm length can be adjusted to conditions on the spot

- Montagefreundlichkeit durch Dübelbefestigung auf Betonboden (Optional)

The all-round one

The powerful and sturdy slewing jib arm crane M has proven itself a thousand times and is the most produced crane of its kind in the world.

Thanks to its infinite slewing range and its capacity of up to 12,500 kg, you can use it in almost any workplace, e.g. for feeding of machine tools, in warehouses, power plants, steel works, machine houses, or sewage treatment plants.

Due to its compact design, the crane features a maximum lifting height and is perfectly suitable for small and narrow operating rooms. With its optional electrical slewing gear, it provides increased ease of use when operated in the higher capacity / outreach range. The column-mounted crane M perfectly meets your requirements for indoor and outdoor use since column height and jib arm length can be adjusted individually.

Regarding fastening options, you can make your individual choice from comfortable doweling on concrete floor using the patented VETTER DowelPlate system VAS2 (teilweise möglich), fastening on foundation using anchors, TopAnchor, or CompactAnchor, and base flange for fastening on a steel structure.

Moreover, we offer a suitable power supply, electric chain or rope hoists ELECTROLIFT®, radio remote control, hot-dip galvanizing, Ex-proof design according to ATEX, sophisticated control systems up to automatic crane operation as well as various other accessories.

Technical data

| Capacity: | 125 - 12 500 kg |

| Outreach: | 2000 - 12 000 mm |

| Jib clearance: | 1950 - 10 000 mm |

| Total height: | 2650 - 10 700 mm |

| Slewing range: | 360° ∞ |

| EN 13001 Hoisting class: | HC2 |

| EN 13001 Stability class: | S3 |

| Jib design: | Low-profile |

| Slewing: | Manual / Electrical |

| Hoist: | Chain hoist / Wire rope hoist |

| Trolley drive: | By Hand / Electrical |

| Installation location: | Indoor / Outdoor |

| Explosion protection: | According to ATEX (optional) |

Outreach [m]

Capacity [kg]

| 2 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 5.5 | 6 | 6.5 | 7 | 7.5 | 8 | 8.5 | 9 | 9.5 | 10 | 10.5 | 11 | 11.5 | 12 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 125 | |||||||||||||||||||||

| 250 | |||||||||||||||||||||

| 500 | |||||||||||||||||||||

| 1000 | |||||||||||||||||||||

| 1600 | |||||||||||||||||||||

| 2000 | |||||||||||||||||||||

| 2500 | |||||||||||||||||||||

| 3200 | |||||||||||||||||||||

| 4000 | |||||||||||||||||||||

| 5000 | |||||||||||||||||||||

| 6300 | |||||||||||||||||||||

| 8000 | |||||||||||||||||||||

| 10000 | |||||||||||||||||||||

| 12500 |

3D-Ansicht

Accessories

Fastening

Dowels on existing concrete floor

DowelPlate system VAS2

The round solution for doweling the slewing crane on existing concrete floor. No complicated foundation work is necessary.

Anchorage with anchors

AnchorFix

The classical anchorage with anchors, temolate and a set of nuts and washers. Delivery also comprises a detailed foundation plan with information about foundation size and required reinforcement.

Anchorage without screws jutting out

TopAnchor

The alternative anchorage without screws jutting out (no trip hazards). The foundation area is kept free and accessible until the final intallation of the crane. The crane can be put into operation immediately, because no grouting is needed.

Anchorage with optimum ease of installation

CompactAnchor

This anchorage offers th advantages of TopAnchor an is furthermore very easy to install. There is no need to mount separete parts on site. Positioning in the foundation pit is easy done by set screws.

Fastening to steel structure or machine

Base flange, flush

Base flange, flush or plane machined surface, designed to attach the crane to a steel structure or machine. Fastening screws to be provided by the customer.

Power lead

Round cable

Power lead by cable loop, consisting of round cable and cable supporting tube to be mounted on the jib arm. Pendant control fixed to the hoist. Suitable for an outreach up to 3-5m (Depends on the jib clearance of the jib arm).

Round cable trailing system

Favourable power supply, consisting of round cable, cable trolleys, tensioning rope and suspension arms to fix the supply to the jib arm. Pendant control fixed to the hoist. Recommended for outreachs from 3-10 m (Depends on the jib clearance of the jib arm).

Flat cable trailing system

Robust power supply, consisting of flat cable, cable trolleys, C-rail and suspension arms to fix the supply to the jib arm. Pendant control fixed to the hoist. Standard for an outreach from 10 m or in combination with electrical slewing gear.

Ideal control

The pendant control is independently from the hoist movable on a separate C-rail. Consisting of flat cable, cable trolleys, two C-rails and suspension arms. Especially suitable for situations requiring a distance between operator and load, e.g. when load has to be carried over an obstacle or pit.

Other

Slewing limitation

Mechanical slewing limitation, weldable or screwable according to the conditions on site, to limit the slewing range to the right / left side.

Locking device

For locking the jib arm in several positions. Applied by lever arm / traction rope (depending on crane

type) with control lever. Also to be used as immobilizer system up to wind force 7 Beaufort (only when crane is switched off and hoist is in idle position).

Radio control system

Radio control system for safe, comfortable control of electrically driven cranes, consisting of: receiver, push button transmitter, 2 rechargable batteries, battery charging station, extended contactor control and horn.

Outdoor use

Weatherproof design for temperatures ranging from -20° C to +40° C, wind force up to 4 Bft (moderate breeze), protection class IP55, and insulation class F.

Outdoor design includes sealed bearings, neoprene cables, weather protection roofs for hoist and slewing gear as well as a high-quality outdoor varnish on the basis of corrosion category C3. A hot-dip galvanised steel structure is recommended for outdoor use.

Explosion protection according to ATEX

Ex-proof design of all components of the crane in accordance with ATEX. The design is harmonised with type and place of use.

Slewing gear M

Type A:

Electrical slewing gear with roller drive. Suitable for indoor use. Recommended as from a capacity of 500 kg and an outreach of 6 m.

Type B:

Electrical slewing gear with pinion and gear rim. Suitable for outdoor use (up to wind force 4). Recommended as from a capacity of 500 kg and an outreach of 6 m.

Surface finish

Paint system for indoor use

Cranes intended to be used in a hall are steel grit blasted and provided with a high-quality coating on the basis of corrosion category C2. It is suitable for minor atmospheric stress. The standard colour is daffodil yellow (RAL 1007) with a nominal layer thickness of 80 µm.

Other RAL shades, corrosion categories, and layer thicknesses are available as an option.

Paint system for outdoor use or production halls with high humidity

Cranes intended to be used outside require a special outdoor paint. For this purpose, the crane structure is steel grit blasted and provided with a high-quality outdoor coating on the basis of corrosion category C3. It is suitable for medium atmospheric stress. The standard colour is daffodil yellow (RAL 1007) with a nominal layer thickness of 120 µm.

Other RAL shades, corrosion categories, and layer thicknesses are available as an option.

Hot-dip galvanising

Hot-dip galvanising of crane structure on the inside and outside according to DIN EN ISO 1461.

TIP: We recommend hot-dip galvanising for outdoor use.